A Business Unit of Walter Tosto

Founded in 1947, Officine Maraldi Bertinoro S.p.A. has made its name in the world serving the foremost plant developers with customized products such as pressure spheres, reactors, refining columns as well as low-temperature and cryogenic storage tanks.

By combining large volumes with absolute precision, Maraldi has achieved an international reputation as one of the top suppliers of pressure storage spheres which have been installed in more than 300 petrochemical plants around the world.

In 2019 the group of companies Tosto Group acquired the experience and expertise, the brand and the references of the Maraldi legacy and employed key personnel from Officine Maraldi Bertinoro.

The Group

The Tosto Group, with over 1300 employees, consists of three major Companies: Walter Tosto SpA (Italy), its subsidiary Walter Tosto WTB Srl (Romania) and Belleli Energy CPE Srl (Italy) which are recognized as the biggest manufacturers in Europe and leading worldwide suppliers of critical and long lead process equipment for Refineries, Fertilizer Plants, Chemical and Petrochemical Plants, Nuclear and Power Plants.

Maraldi belongs to the Tosto Group as a Business Unit of Walter Tosto SpA; its core activities are related to the manufacturing of Low-Temperature & Cryogenic (Storage) Tanks and Pressure Spheres.

The Tosto Group has added to the Maraldi experience financial strength and solidity and a manufacturing capacity which is the largest in Europe and among the largest worldwide.

From the origins to nowadays

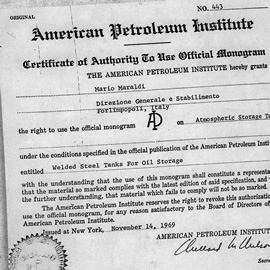

Maraldi was founded in 1947 and through the last 70 years – under different designations such as “Mario Maraldi” and lately “Officine Maraldi Bertinoro” – became one of the Italian landmarks in design and manufacture of pressure equipment (columns, reactors, vessels), storage tanks, cryogenic tanks and spherical tanks.

In the early years Maraldi contributed to producing storage tanks for the most important Italian refineries, and started to consolidate its experience and professionalism. This experience has led to it becoming a leader in the sector of Oil & Gas equipment. Over time new plants and new types of production have been added to the original nucleus, in the needs of other industries ranging from iron metallurgy to sugar production, all contributing to increasing the scope of the group’s competencies.

Later on Maraldi has been able to deal with the evolution of the market by adopting an effective strategy of specialization in its sector.

This strategy entails the capacity to identify and develop important factors of diversification, thus enabling the company to concentrate on products with a higher engineering content such as cryogenic tanks and pressure storage spheres.

Mission

Our aim is to consolidate, continue and further develop our achievements, by generating a positive impact for people and environment. Our daily motivation is supported and driven by the history of the Group, the established processes, consolidated know how, the continuous growth through investments and past and ongoing supply experiences.

Vision

To be the “first call” and preferred choice for the world’s leading End Users, Technology Licensors and Main Contractors within our business. To consistently exceed our Clients’ expectations through innovative ideas, new technologies and value-adding solutions, inspired by our vocation for research and sustainability.

Our shared values are the guidelines of the company activities

Transparency

We strive to set up a lean internal structure in order to guarantee an open book approach through direct contact at all operational levels for a quick decision making process.

Continuous improvement

We set high objectives and, through improvements at all levels, we push to achieve the best results.

Quality

We do not compromise; we have a passion for the best quality.

Safety

We are committed to perform all our processes in a safe and accident free environment in order to guarantee health and safety to all our people.

Innovation

Our constant research for new technology solutions make us an innovative company, wishing to share the results with our customers.

Flexibility

We are open and quickly adapt to new market requirements. We strongly motivate and train our employees in order to rapidly and efficiently adjust to the different requests.

Social consciousness

We have a duty to act in the best interest of our environment and society as a whole.

Quality System Certification

A customer-oriented mission for maximum quality

The Group Quality Policy involves the management of all the activities and pursues the aim to guarantee quality standards at all the organization levels.

At this purpose, the elements necessary for an accurate planning of the business processes are continuously collected and evaluated.

By following the Quality Management Program of the Tosto Group, our organization aims to maximize the efficiency of the manufacturing activities and the products quality in order to guarantee full satisfaction of the customers.

Adequate competences and knowhow of the employees are essential requirements to guarantee that the processes are performed in an efficient and successful way. The availability of the most advanced tools and machinery allow us to obtain the expected quality level and high productivity.

The high quality of the procured materials is another important aspect together with the capability to identify qualified suppliers and to create strong partnerships with them.

Thanks to the strong interaction among all the business functions, the fabrication activities are managed with absolute competence to promptly prevent negative situations and solve any possible issue.

Regular checks of the quality system status and corrective/preventive actions ensures continuous improvement of the organization.

Certifications

Maraldi operates according to a Quality Management System pursuant to ISO9001 standard. As part of the Tosto Group, the company’s attention for continuously improving the activities quality is stated by the following certifications:

- ISO 9001

- ISO 3834-2:2006

- ISO 14001

- National Board R Symbol Certificate

- SELO Pressure V

- SELO Boiler

- National Board

- ASME U

- ASME U3

- ASME U2

- Asme S

- ASME N

- AEO – Full

- PED H, H1

- ASME NPT

- CU TR Compliance Certificate

- CU TR Certificate for Heat Exchanger

- Asme PP

- Asme NS

- Asme NB

- Gost for heat exchanger

- Gost for Pressure Vessel

- SQL China

Our commitment to safety and sustainability

By following the shared Tosto Group policies, Maraldi is committed to guarantee health and safety of all the people working within the company, as well as the protection of the environment. In this regard, precise preventive safety measures have been implemented and environmental policies have been defined in order to minimize injuries and impacts on the environment.

Health and Safety

Our safety policy embraces all the organization levels in order to eliminate dangerous situations and behaviors that can cause accidents or injuries.

Safety is indeed placed at the same level of productivity, efficiency, quality, environment and other factors of significant importance for the company.

We believe that all the accidents can be prevented through the application of the best technologies in the workplace and through an appropriate training at each organizational level, in order to define and assure that skills and responsibilities are in line with the perspective of continuous improvement. All the employees are responsible for applying security policies and they are required to work in a safe manner in order to eliminate any risk of accident.

Maraldi favors the use of personal prevention devices to improve security and ensure workers’ health.

The safety warranties at work are a key aspect in the implementation of manufacturing activities and indirectly contribute to ensure the maintenance of quality standards of the products along the time.

Environment

The strong connection with the territory makes the environmental protection part of Maraldi’s philosophy. For this reason, the company is committed to define, observe and enforce the best practices for the reduction of all possible environmental impacts. This intention was achieved by the ISO 14001 certification, which formalizes the respect and protection of the environment by the company, that is committed to reduce the emissions.